Proven Performance

The World's Safest Underground Storage Tanks

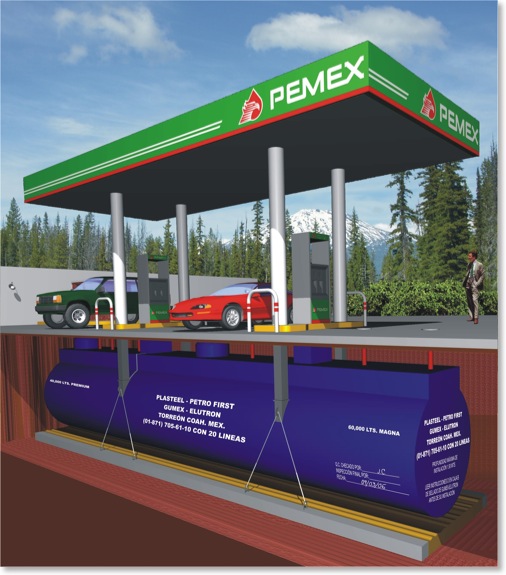

The Plasteel® PetroFirst™ Unitized Fueling System

The Plasteel® PetroFirst™ Unitized Fueling System is UL Listed and Tested per UL Standard 58 and UL Standard 1746, Part II and Part III. The first PetroFirst™ Unitized Fueling System was installed in 1997.

The Plasteel® PetroFirst™ Unitized Fueling System is UL Listed and Tested per UL Standard 58 and UL Standard 1746, Part II and Part III. The first PetroFirst™ Unitized Fueling System was installed in 1997.

Plasteel® PetroFirst™

Marketing Benefits

Maximum environmental protection

Marketing Benefits

Maximum environmental protection

- Proven structural performance of steel

- Proven corrosion protection performance of FRP

- External piping eliminated, 80% of leaks are from piping

- Entire fueling system under canopy

- No separate underground tank and piping real estate required

- Maximize profit of real estate used for fuels marketing

- More options to fit fueling into existing land or parking lot

- More options to use land for parking, traffic flow, car wash or other profit center

- Dispensers mounted directly above the storage tank

- Reduced manpower and supervision

- Reduced on-site construction time

- Reduced potential liabilities (safety risk)

- 15% plus savings

- Lower long term operating costs

- No external piping = lower insurance premiums

- Proven safety and security performance of FRP / steel based tank

- All containment sumps and surface covers under protection of canopy

- Eliminates concrete canopy column footings

Plasteel® PetroFirst™

Engineering Benefits

Design Components

Engineering Benefits

Design Components

- Pre-engineered, certified and U.L. Listed

- Pre-fabricated tank and pipe system

- Factory installed, self-contained internal steel piping

- Patented integral canopy column foundation connections

- UL Standards 58 & 1746 Compliance

- UL Listed Plasteel® Elutron® FRP Jacketed Double Wall Underground Tank

- UL Listed Plasteel Composite® Double Wall and Single Wall Underground Tanks

- 100% Interstitial monitoring capability of system

- Choice of tank capacities

- Multiple system configurations

- Multiple compartment tanks for blending

- Future bio-blended petroleum fuels compatibility

- Strength of welded steel piping

- All welded connections

- No onsite product piping installation

- Ready for containment sump installation

- Welded steel/FRP secondary containment piping trough (strength and corrosion protection)

- Interstitial monitoring for piping system

- Factory tested leak tight